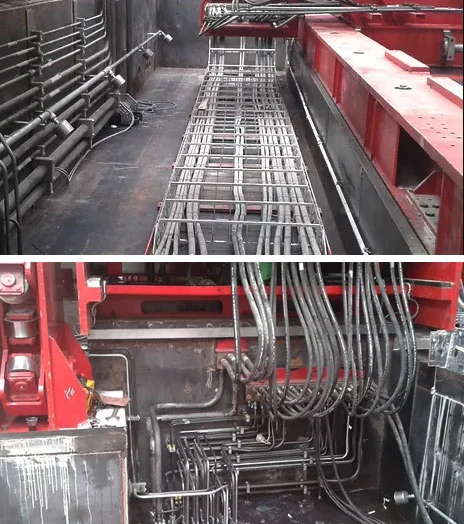

Hydraulic Pipes

Hydraulic circuit pipes are hollow pipes used to systematically transport liquid or gas fluids from one place to another.

Appropriate hydraulic circuit pipe selection is made by looking at the flow pattern, pressure and temperature according to the type of product being transported. It is used more intensively in industrial areas, ships, yachts and fire systems.

Hydraulic line pipes vary in diameter from Q5mm to Q42mm and according to thicknesses of 1mm-5mm. The pipes are phosphated to prevent corrosion and proper connection of the pipes is necessary to reduce leaks and avoid noisy operation in the system.

There are points to be considered in pipe connections. These ; Cleanliness, Support, Function.

Cleaning the hydraulic circuit pipes

Dirty oil is the biggest cause of malfunctions in hydraulic systems. Sensitive materials are particularly susceptible to problems caused by assembly residues. For this reason, the assembly should be done in a clean environment as much as possible and the piping should be cleaned after the assembly.

Supporting

When the fluid passing through long hydraulic pipes is suddenly stopped or reversed, they are subject to vibration and shock. This causes the connections to loosen and eventually to leaks. Therefore, pipes should be supported with pipe clamps at appropriate intervals. Pipe clamps should not be attached close to the fasteners to facilitate the assembly of the fasteners. It is appropriate to use wood or plastic as a clamp.

Function

There are some points to be considered about the functions of the lines.

Pump suction pipe diameter should be larger than the pipe diameter in the pressure line. The connection from the tank to the pump should be as short as possible. Elbows or similar fasteners at the entrance should be avoided.

Due to the vacuum in the suction of the pump, the connections in the suction must be tight to prevent air entry.

Restricted passages in return lines cause pressure to rise and power wasted unnecessarily. The pipe diameter must be suitable to keep the flow rate low.

The distance between the cylinder and the speed control valves should be short.

Sufficient radius should be given for turns.

Please contact us for detailed information about our products.