CNC Turning Processing

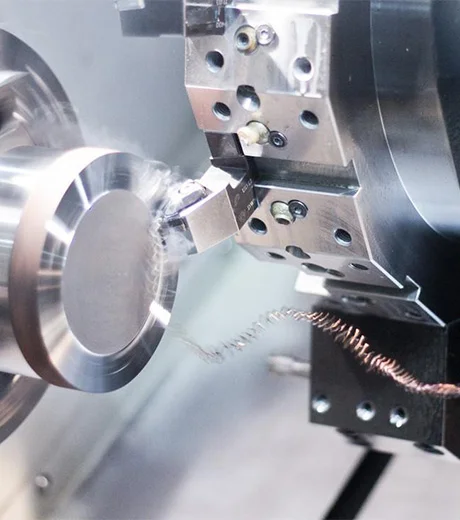

CNC lathe machining is a process used to manufacture parts using a CNC (Computer Numerical Control) machine. CNC lathes can be programmed to edit the surface of a rotating part using specific cutting tools.

CNC machining machines are incredibly precise machines. They have the ability to cut precisely as wide as a human hair (0.003 mm).

How is CNC Lathe machining done?

The process starts with creating a part design. First, a three-dimensional part design is created using a CAD (Computer Aided Design) software. This design is then converted to a CNC using CAM (Computer Aided Manufacturing) software. This CNC program determines which paths the lathe will follow the cutting tools, which end tools are connected and when.

During the turning process, the part moves along a head spindle lines and the next end tools along a certain path. Cutting tools cut and shape the material on the part so that the part has the desired size, shape and surface roughness.

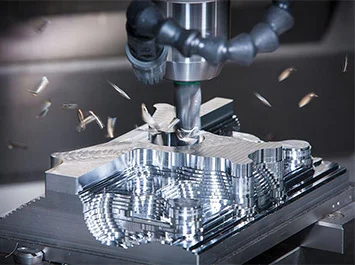

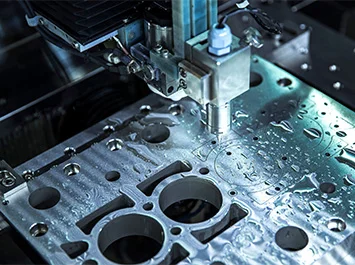

What types of manufacturing are possible?

The CNC turning process can be applied to many different materials such as metal, plastic, wood and composite materials. The turning process is particularly suitable for the production of precision tolerance requirements and is used in mass production.

The following operations can be performed on CNC lathes: Cylindrical turning, Profile turning, Face turning, Grooving, Screwing, Drilling, Guide screwing, Reaming, Hole enlargement, Grooving into the hole, Grooving on the forehead of the part, Knurling, Curve and chamfer operations etc.