Machining Center

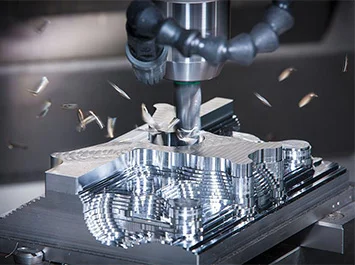

CNC machining center is the general name given to machines that combine machining technologies and can automate all these. Machining center refers to the machine tool, which has the function of automatic tool change, and then executes the multi-process machining after the workpiece is clamped once. With CNC machining centers, we can apply different machining methods very precisely and quickly.

Machining centers are generally divided into horizontal, vertical and universal machining centers by the relative position of the spindle and worktable.

Advantages:

CNC machining center has many advantages. One of its biggest advantages is that it prevents time loss and enables mass production. The setting time of the machine in the CNC machining center is also very short. Adjustment, measure, control, manual movement etc. The loss of time caused by such reasons is eliminated.

It also provides an advantage in terms of storage because it needs less space. After the changes to be made on the part are entered in the relevant part of the program, mass production can take place.

Processing units are easy to access. During processing, the machine provides maximum productivity. Edge materials are easy and quick to load, as well as easy to change materials. High energy efficiency is another advantage.

Types of CNC Machining Center

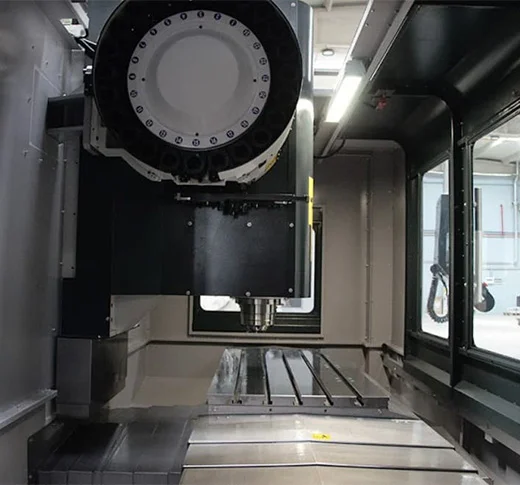

CNC machining centers have many different types and variations according to application areas, power needs and processing technologies. Machining centers are generally divided into horizontal, vertical and universal machining centers by the relative position of the spindle and worktable.

Horizontal Machining Center

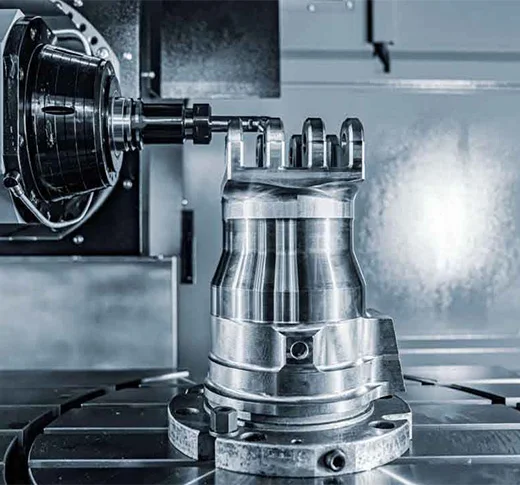

It mainly refers to the spindle axis and workbench parallel machining center cluster, which is suitable for processing box-type parts. In general, cnc horizontal machining centers are stronger, more rigid and have higher chip capacity than cnc vertical machining centers.

Vertical Machining Center

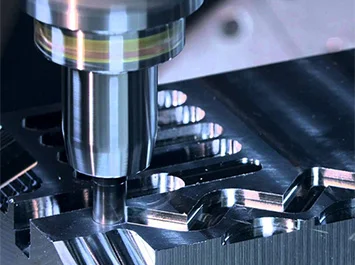

It is one of the most typical and standard machining benches used in the manufacturing industry. It mainly refers to the spindle axis and table vertical adjustment of the machining center for the processing of plate type, disc type, mold and small shell complex parts.

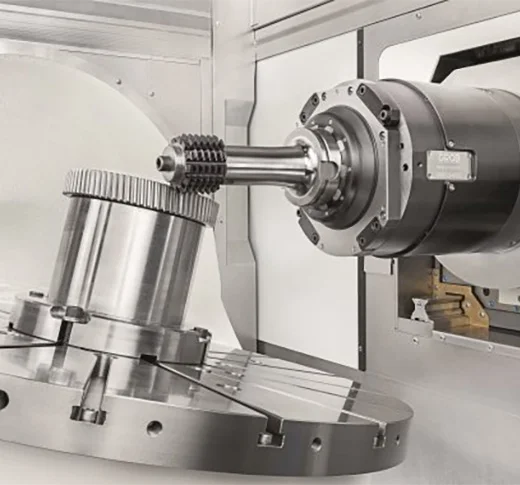

Universal Machining Center

It is a multiprocessor axis link type machining center. Versatile flexibility between milling machines as they have vertical and horizontal milling spindles and can be expanded in many ways. It is suitable for machining knives, dies, cutting tools and other workpieces with complex space surfaces.