Hydraulic Cylinder Piston Manufacturing

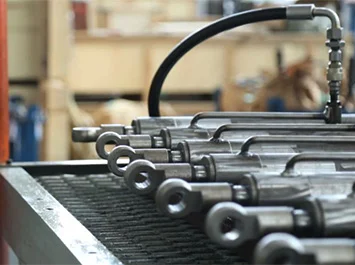

Hydraulic pistons consist of hydraulic cylinder, hydraulic shaft, piston, piston seal, throat bearing, dust seal, o-ring, throat and cylinder base. As the diameter of the hydraulic cylinder increases, the force applied will increase in direct proportion. The piston, which moves in the hydraulic cylinder, seals the pressure with the other intermediate elements and applies force linearly. In addition, different methods are used to prevent the wear of the cylinder interior due to continuous movement and to ensure that it works in a healthy way. Thanks to the cylindrical grinding process applied to the hydraulic shaft and hard chrome plating afterwards, hydraulic pistons can be used for a longer life.

In order for hydraulic piston systems to work properly, they must be designed correctly. The correct calculation of the force desired to be applied will ensure that the hydraulics work in the best possible way.

When ordering a hydraulic piston (cylinder), we arrange the diameter of the piston we produce in line with the wishes and needs of our customers, the seal kit, and the weight that the piston will lift.

Usage areas of hydraulic piston

Hydraulic pistons used in modern production areas are the first choice of many businesses. According to the force applied by the piston, hydraulic pistons are used in most of the machines. The most commonly used machines are printing machines, textile machines and construction machines.

Hydraulic piston manufacturing

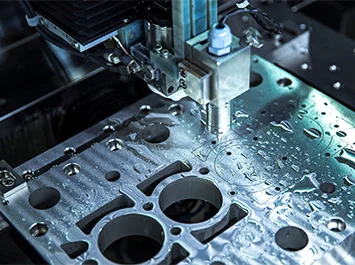

The hydraulic cylinder, which forms the outermost part of the hydraulic mechanisms, is made of steel material called ST52. This material can vary according to the resistance of the work to be done. It is applied by calculating the wall thickness of the steel according to the pressure to be applied by the piston that will work in the system.

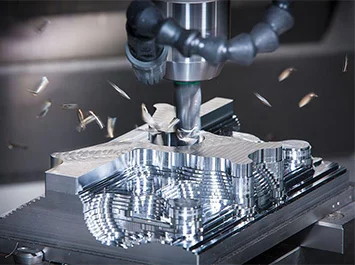

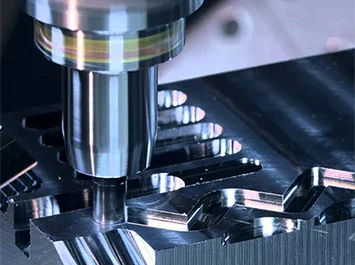

After the wall thickness of the hydraulic cylinder is calculated and produced, the hydraulic shaft is produced. Generally, pure steel materials such as Ck45, 4140 and tempered 4140 are used for shafts. In order to harden this pure steel, induction process is applied after the turning process. Afterwards, it is applied for pure steel use with cylindrical grinding process and made usable in the mechanism with hard chrome plating process.

With the turning process applied on the material, unwanted protrusions such as burrs on the material are removed. In addition, with this process, the steel is thinned and brought to the desired size. Then, with cylindrical grinding, the surface smoothness of the steel is increased and it becomes suitable for fine applications. With the hard chrome plating process, the steel is made harder, its resistance is increased and friction is largely eliminated. Slipperiness is provided, strength is increased, surface smoothness is reduced to a minimum.

It is produced by honing the inside of the piston moving in the hydraulic cylinder. The dimensions of the hydraulic piston to be made should be adjusted according to the stroke and pressure demand of the work to be used in the application. Apart from this, intermediate products that will serve as sealing should be preferred according to the diameter of the piston.

Miscalculation of hydraulic cylinder and piston diameters and deterioration due to use should be corrected with piston rod maintenance. The calculations and controls of the hydraulic mechanism must be done carefully.