Milling

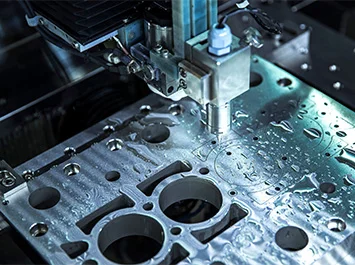

Milling is one of the machining methods. It is called milling when the CNC milling machine makes certain movements on the surface or around the raw material to process that part.

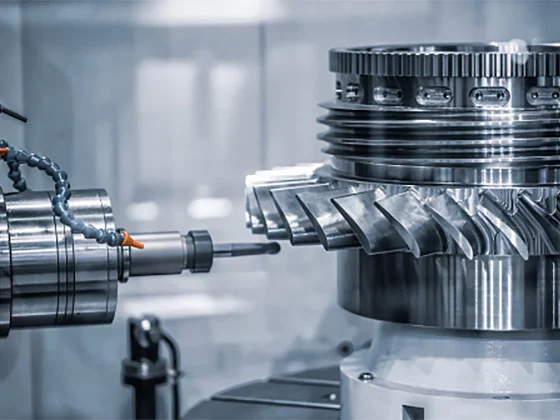

While milling, the workpiece must remain stationary and never move. Any vibration that may occur will cause the milling spindle to touch the workpiece, rendering it useless. Milling machines can be used on many different surfaces and for many different purposes in cutting and shaping processes, such as gear cutting, grooving, slotting, chamfering, side machining, pool processing, dividing angled surfaces into parts, shaping workpieces with different angles can be used at work.

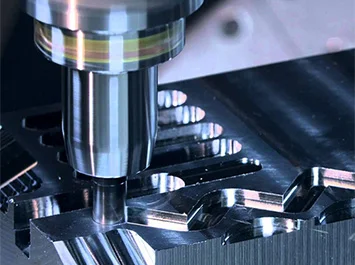

Cutting tools with different geometries are used to obtain different surfaces and shapes with the milling operation.

The most used milling cutters are; scan heads, end mills, drills, insert end mills, insert drills, reamers, ball mills, taps.

Milling machines remove chips with the movements of the cutting tools. It has mobility. This mobility allows the level differences that cannot be realized on the lathe to be realized easily. One of the differences between a lathe and a milling machine is whether the workpiece rotates or not.