Hydraulic Cylinders

We manufacture hydraulic cylinders in accordance with the connection types, sealing elements, working pressure, ambient temperature, place and conditions of use and in line with the special requests of our customers.

Hydraulic cylinders are circuit elements that convert hydraulic energy into mechanical energy and are used to obtain linear motion.

They can convert the hydraulic energy produced by the hydraulic pump into linear or angular motion with the help of a cylinder. Hydraulic cylinders can be of various specifications and sizes, depending on the area of use.

The areas where they are generally used; Hydraulic presses, construction equipment, cranes, platforms, plastic injection machines, factories, agricultural machinery, mines, iron and steel industry, elevators, dam covers, ship covers.

Various hydraulic cylinders such as single-acting, double-acting, tandem, telescopic are used in different applications according to their intended use.

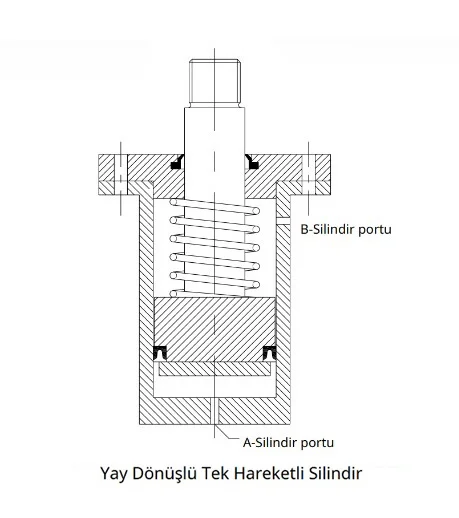

Single Acting Cylinders

Single acting cylinders are elements that move forward and backward. These pistons move forward thanks to the hydraulic oil pressure applied to them. However, they provide their movement in the reverse direction not with the body pressure, but with their own piston weight or the weight of the load on the piston. Because the pressure acts in only one direction, it is called a single-acting piston.

The best example of a single acting hydraulic cylinder is the hydraulic jack, which is in almost every car and represents the most common application of a gravity return cylinder.

Single acting cylinder is used in many machines. For example, in hydraulic elevators, construction machines, agricultural machines. These cylinders can be produced in various sizes according to usage and needs.

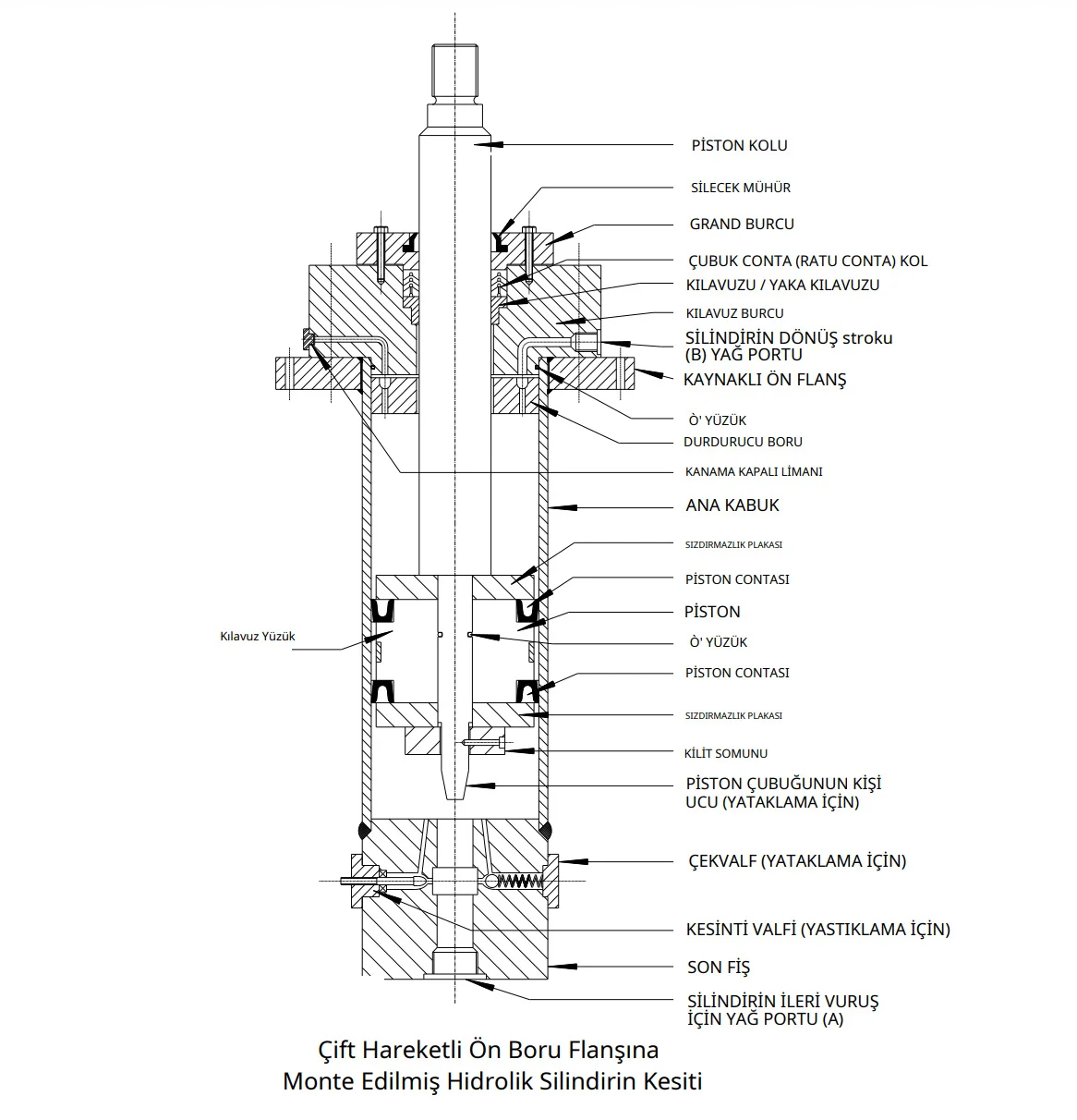

Double Acting Cylinders

These pistons also move in the forward and backward direction. The forward and reverse movement of these pistons is provided by hydraulic oil pressure. Both forward and backward movement are adjusted and moved under user control.

The difference from single-acting is that all movements are pressure dependent. It is used very frequently, especially for construction machines. These cylinders can also be produced in desired dimensions.

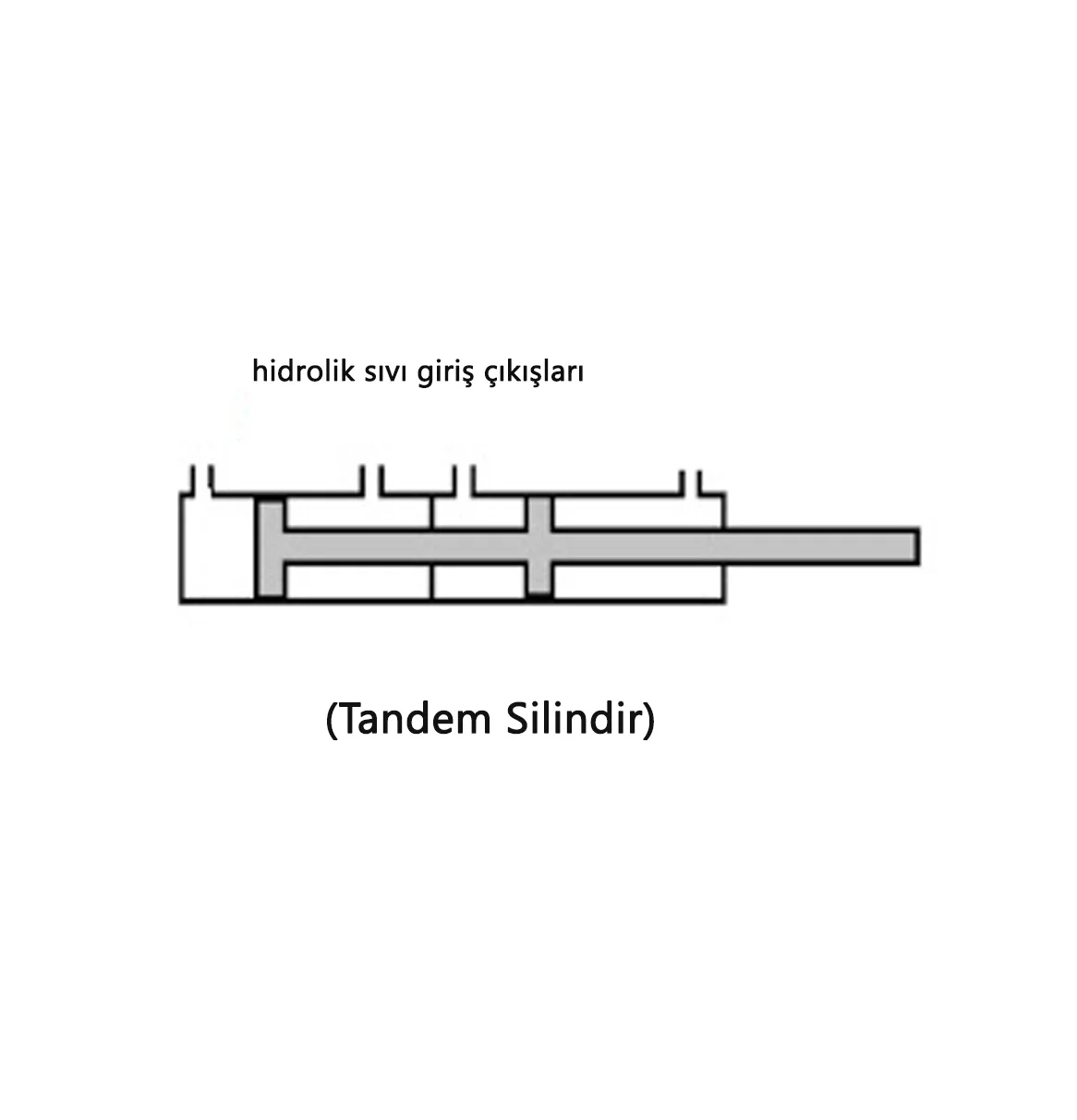

Tandem Cylinders

It uses multiple pistons connected via a common rod to generate relatively high force from low feed pressure and small bore.

It is designed for applications where high force must be produced in a narrow radial clearance where significant axial length is available. A tandem cylinder functions as two single rod end cylinders connected in-line with each piston connected to a common rod, as well as a second rod extending from the rod end cap. Each piston chamber is double-acting to produce much higher forces without an increase in fluid pressure or bore diameter.

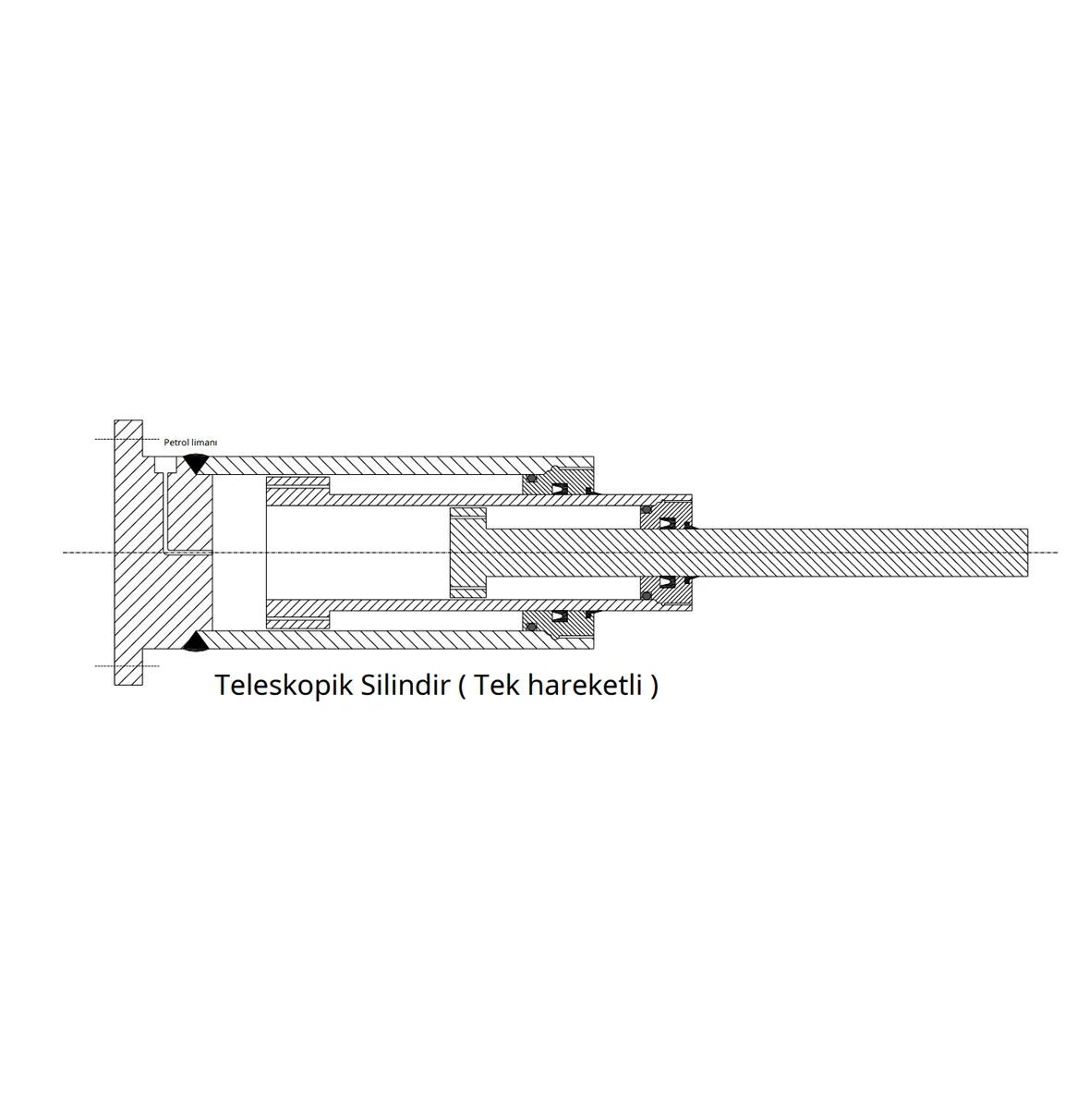

Telescopic Cylinders

Telescopic hydraulic cylinders are ideal for applications where the force field is limited. Telescopic cylinders provide longer reach, making them perfect for heavy construction machinery, dump trucks and other industrial mobile vehicles.

Spare telescopic hydraulic cylinders are a great way to keep your industrial heavy machinery running.

Specially designed telescopic cylinders can be made with load capacities in mind, allowing for enhanced capacity, stroke lengths and number of stages that standard telescopic cylinders cannot meet.

Choosing the right telescopic cylinder design also requires knowledge of the number of stages, stroke length and the largest OD stage (outside diameter).

Common industrial mobile equipment utilizing telescopic cylinders: garbage trucks, platform truck trailers, front loaders, side loaders, drilling rigs, trailer transfer, agricultural machinery, construction machinery.